The Global Expansion of Waterproof Junction Boxes in 2025

Waterproof junction boxes have become one of the fastest-growing electrical protection components in the global low-voltage and outdoor electrical markets. As industries demand safer connections, long-term outdoor durability, and compliance with international waterproofing regulations, manufacturers across Asia, Europe, and the Middle East are accelerating innovations in IP-rated enclosure systems.

In regions such as Africa, Southeast Asia, and South America, governments and commercial sectors are rapidly transitioning from older open-type cable joints to modern waterproof junction boxes that deliver superior moisture resistance, UV protection, and mechanical stability. The rapid development of renewable energy, smart lighting, public safety infrastructure, and outdoor power distribution is accelerating this shift.

2. Market Overview

The global waterproof junction box market is projected to surpass USD 6.2 billion by 2030, driven primarily by outdoor infrastructure upgrades and expanding smart city initiatives. Asia-Pacific remains the largest manufacturing base, while Africa and Latin America represent the fastest-growing consumer markets.

3. Global Demand Drivers

Several factors continue to accelerate worldwide adoption:

- Growth in outdoor LED lighting networks

- Expansion of highway and railway electrical systems

- Surge in off-grid and renewable energy installations

- Increased safety regulations in marine and construction industries

- Demand for corrosion-resistant and UV-resistant enclosures

4. Material Innovations

Manufacturers are developing lightweight yet high-strength polycarbonate and nylon junction boxes engineered to withstand harsh UV exposure, chemical splashes, and saltwater corrosion. Reinforced PA66 nylon models are increasingly adopted in automotive, marine, and industrial systems where mechanical shock resistance is critical.

5. Waterproof Standards

IP65, IP66, and IP68 ratings remain the global benchmarks for waterproof junction box solutions. IP68 is specifically favored for underground cable installations, coastal engineering, and high-humidity industrial environments.

6. Installation Methods

Modern waterproof junction boxes support a wide variety of installation environments, including wall-mounted, pole-mounted, underground, in-ground vaults, and marine-grade installations. Cable entries are designed with rubber compression seals, threaded glands, or molded cable bushings to ensure airtight protection.

Innovative modular systems allow electricians to customize internal terminal layouts, fuse blocks, DIN-rail components, or waterproof connectors. The rise of “tool-less wiring modules” in 2024–2025 significantly reduced installation times in large-scale construction projects.

7. Global Market Segments

The waterproof junction box market can be divided into several core segments:

- Outdoor Public Infrastructure: highways, bridges, street lighting, surveillance systems

- Commercial & Industrial Facilities: factories, warehouses, production lines

- Marine & Offshore: docks, oil platforms, coastal stations

- Renewable Energy: solar farms, wind turbine networks, hybrid power stations

- Residential Outdoor Systems: gardens, pools, smart home exterior systems

Africa remains a strategic emerging region for waterproof junction box demand, particularly in Kenya, Nigeria, South Africa, and Tanzania, where outdoor electrical renovation projects increased by more than 40% in the last five years.

8. Industrial Use Cases

Industrial adoption is driven by the need for electrical continuity under extreme working conditions. Factories dealing with chemicals, heavy dust, or frequent washdowns rely extensively on IP66/IP68-rated boxes to protect sensitive wiring and sensor systems.

In manufacturing lines, waterproof junction boxes safeguard PLC wiring, motor control signals, robotic cable feeds, and low-voltage power distribution. Many industrial-grade boxes now offer flame-retardant materials following UL94 V-0 standards.

9. Urban & Public Infrastructure

Smart cities require waterproof junction boxes to ensure uninterrupted power supply for traffic lights, IoT sensors, street cameras, and electric vehicle charging piles. With increasing adoption of 5G smart poles, IP66+ enclosures have become mandatory.

10. Marine & Coastal Engineering

Coastal regions face continuous exposure to salt, humidity, and UV radiation. Waterproof junction boxes with marine-grade nylon housings or polycarbonate reinforced with anti-UV additives have seen a 60% growth in adoption among shipping ports and offshore wind farms.

11. Future Technologies

Next-generation waterproof junction boxes will integrate real-time temperature sensors, humidity monitoring, and IoT diagnostics to detect cable faults before system failure. Wireless inspection modules are also expected to reduce maintenance costs in multi-site outdoor systems.

12. Global Company Ranking (2025)

Below are the top global manufacturers in the waterproof junction box sector for 2025 (analysis based on production capacity, export volume, and innovation index):

- ABB – Switzerland

- Schneider Electric – France

- Gewiss – Italy

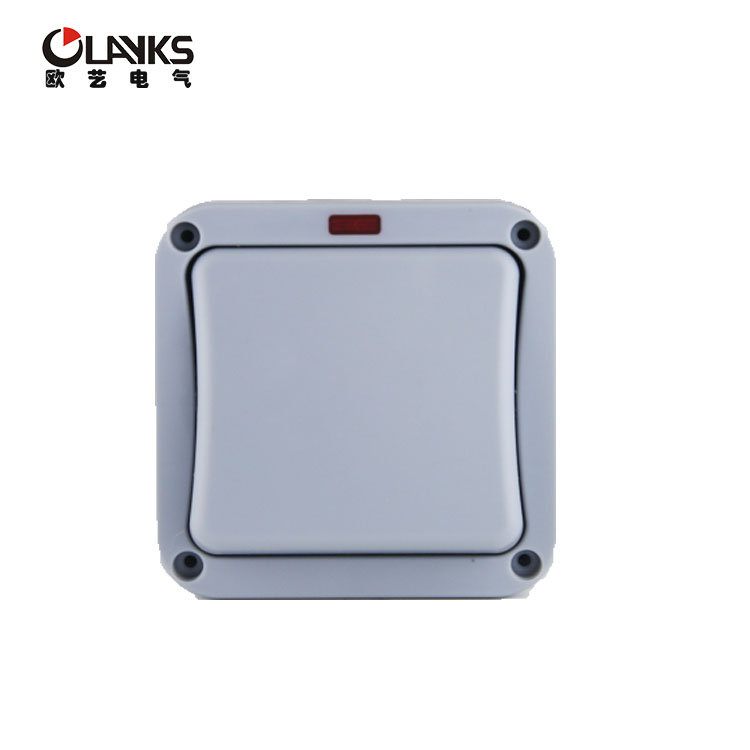

- Olayksele – China

- Legrand – France

- Hensel – Germany

- Eaton – Ireland

- Mencom – USA

- IPCOM – UAE

- TruNorth Electric – Canada

13. Conclusion

As the demand for outdoor electrical safety continues to rise, waterproof junction boxes will remain indispensable across global infrastructure, industrial automation, renewable power, and marine engineering sectors. Manufacturers who invest in material science, waterproof sealing innovation, and smart monitoring technologies will lead the next decade of growth.