Complete Guide to Electrical Enclosures: Protection for Your Electrical Systems

What Are Electrical Enclosures?

Electrical enclosures are protective housings designed to safeguard electrical components and wiring from environmental factors, physical damage, and unauthorized access. These essential components play a critical role in maintaining the safety, reliability, and longevity of electrical systems across various industries.

From simple junction boxes to complex control panels, electrical enclosures come in diverse forms to meet specific protection requirements. They shield sensitive equipment from dust, water, extreme temperatures, corrosive substances, and impact, ensuring uninterrupted operation even in challenging conditions.

Types of Electrical Enclosures

Electrical enclosures are classified based on their material composition, design features, and protection levels. Understanding these variations is crucial for selecting the right enclosure for your specific application.

By Material Type

Metallic Enclosures: Typically made from aluminum, stainless steel, or carbon steel, these enclosures offer excellent durability and electromagnetic shielding. They're ideal for industrial settings where physical protection and interference prevention are priorities.

By Protection Rating (IP Code)

The Ingress Protection (IP) rating system classifies enclosures based on their effectiveness against solid objects and liquids. Common ratings include:

- IP54: Protection against dust and water splashes

- IP65: Dust-tight and protected against water jets

- IP66: Protection against powerful water jets

- IP67: Protected against temporary immersion

- IP68: Protected against prolonged immersion

How to Select the Right Electrical Enclosure

Choosing the appropriate electrical enclosure requires careful consideration of several factors to ensure optimal protection and functionality.

Environmental Considerations

Evaluate the operating environment for:

- Exposure to moisture, water, or humidity

- Presence of dust, dirt, or other particulates

- Temperature extremes

- Exposure to corrosive chemicals or solvents

- Risk of physical impact or vibration

Size and Capacity Requirements

Ensure the enclosure provides sufficient space for:

- Current components with room for heat dissipation

- Potential future expansions or additions

- Proper cable management and routing

- Adequate clearance for maintenance access

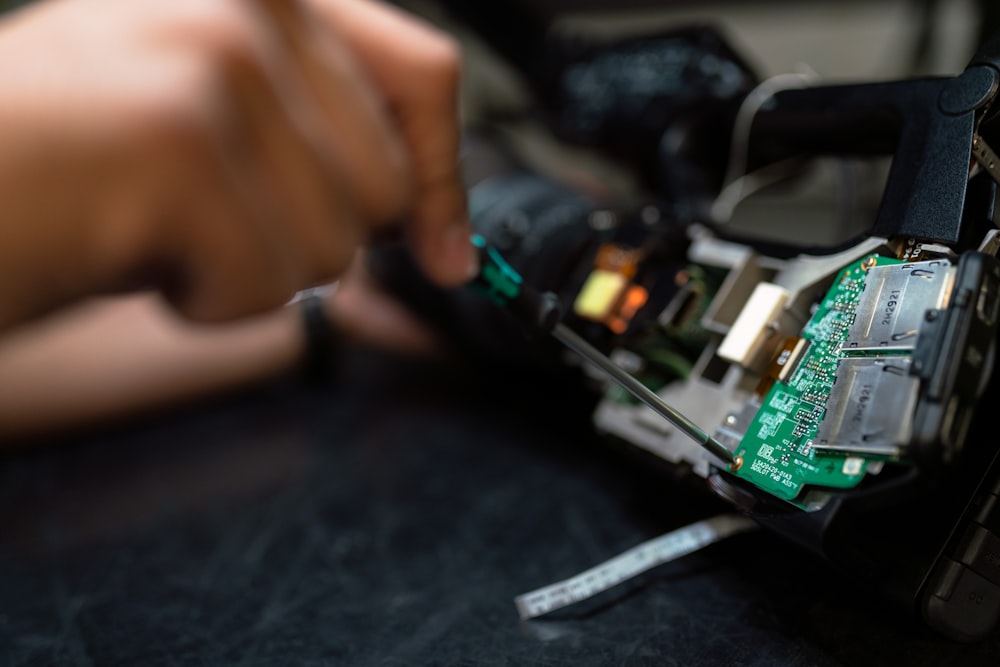

Proper Installation Techniques

Correct installation is crucial for ensuring the enclosure provides the intended protection. Follow these guidelines for optimal performance:

Mounting Considerations

Select appropriate mounting locations that:

- Are easily accessible for maintenance

- Minimize exposure to environmental hazards

- Provide adequate support for the enclosure's weight

- Allow for proper cable entry and exit

Sealing and Gasket Maintenance

Proper sealing ensures the enclosure maintains its IP rating:

- Inspect gaskets regularly for signs of wear or damage

- Ensure surfaces are clean before closing the enclosure

- Follow manufacturer torque specifications for fasteners

- Use appropriate cable glands and conduit seals

Common Applications of Electrical Enclosures

Electrical enclosures serve critical roles across numerous industries and applications:

Industrial Manufacturing

In manufacturing facilities, enclosures protect control systems, motor starters, and PLCs from dust, moisture, and physical damage, ensuring continuous operation of production equipment.

Outdoor Installations

Weatherproof enclosures house electrical components for outdoor lighting, irrigation systems, and telecommunications equipment, protecting them from rain, UV exposure, and temperature fluctuations.

Hazardous Environments

Explosion-proof enclosures prevent ignition of flammable gases or dust in chemical plants, refineries, and grain processing facilities, meeting strict safety standards for hazardous locations.